RELATED PRODUCT BRANDS

EXPLORE OTHER PROMACH BUSINESS LINES

EXPLORE OTHER PROMACH BUSINESS LINES

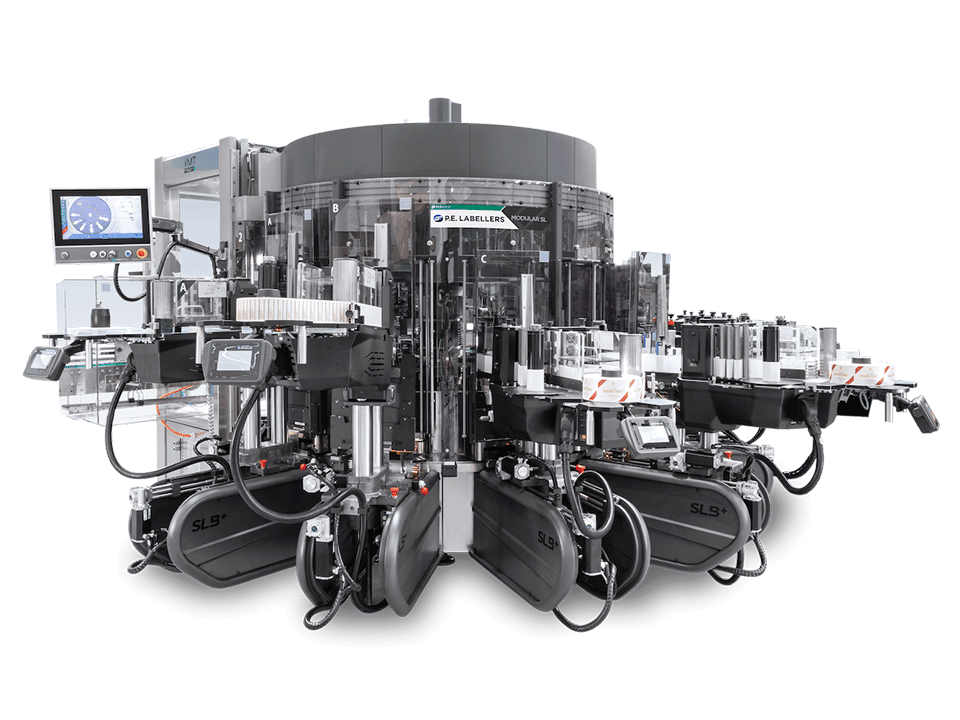

Rigid containers, including bottles, cans, jars, and more, are constantly updated to improve shelf appeal, emphasize new features, highlight nutrition facts, introduce new SKUs, enhance security, and more to win the war for consumer attention. All of these factors impact product labeling needs, and ProMach offers one of the most comprehensive labeling solution portfolios in the industry – from full body sleeves to multi-spot labeling and more – ProMach helps customers maximize the performance of their products on the shelf.

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn more